This post is the beginning of a new chapter in my blogging.

For years, I’ve blogged at The Workbench Diary sharing the ins and outs of my

little conservation practice on the coast of Maine. I’ve regularly posted about

furniture related research, preservation, and recreation with the occasional

glimpse into happenings on my homestead including goats, chickens, gardens,

etc.

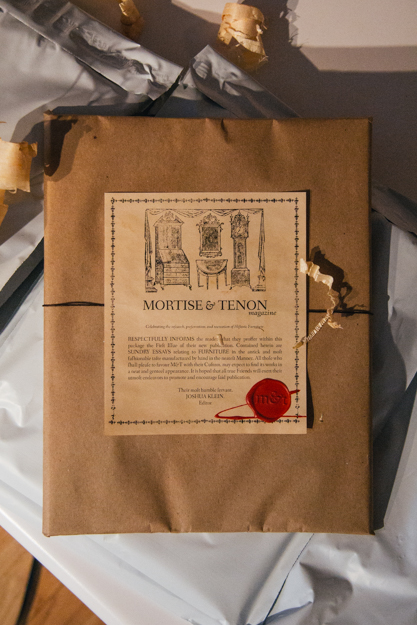

Even as Mortise & Tenon Magazine has been growing and

blossoming far beyond what I ever envisioned, I’ve been maintaining (sort of)

The Workbench Diary alongside. What has been happening lately is that because

so much of my time has been spent on M&T it has naturally started to become

the M&T blog.

As I’ve been sharing these M&T-related blog posts on

social media, I’ve begun to feel like having a blog of a different name from

the Magazine’s was confusing. Additionally, since I have hand-picked a team of

people to work with me now, I really want to give them a voice on the blog. You

will want to hear what they have to

say, readers. These are some of the most passionate hand tool woodworkers

around. As we grow and experiment and test our theories as a team, we want to

be sharing it with you.

So I thought it would make more sense to relocate my

blogging efforts to one regular place. I’ve opened up a new blog on the Mortise

& Tenon website. You’ll be able to find it in the navigation bar by simply clicking

on “Blog”. So, although www.workbenchdiary.com

will remain a live static site, all new posts will be at http://mortiseandtenonmag.com/blogs/blog.

It really isn’t a sad ending, though. It will be the same

stuff only in a different place. So from here on out, readers, follow us at the

M&T website. Everything will be nice and tidy and in one place. (And

commenting will be easier!)